We put our energy into the development of your chain conveyor so you can save energy when running it

A chain conveyor from FM Bulk Handling – Fjordvejs is an energy-efficient and reliable solution. It will reliably move your products all day long, every day, all year round without damaging them and without unnecessary down time.

Our products are always manufactured using tough materials that can withstand daily operations for many years. These materials include steel painted in your preferred RAL colour, hot-dip galvanised or stainless steel, AISI 304 or AISI 316. Our machines are designed to operate 24/7, 365 days a year.

Contact us today

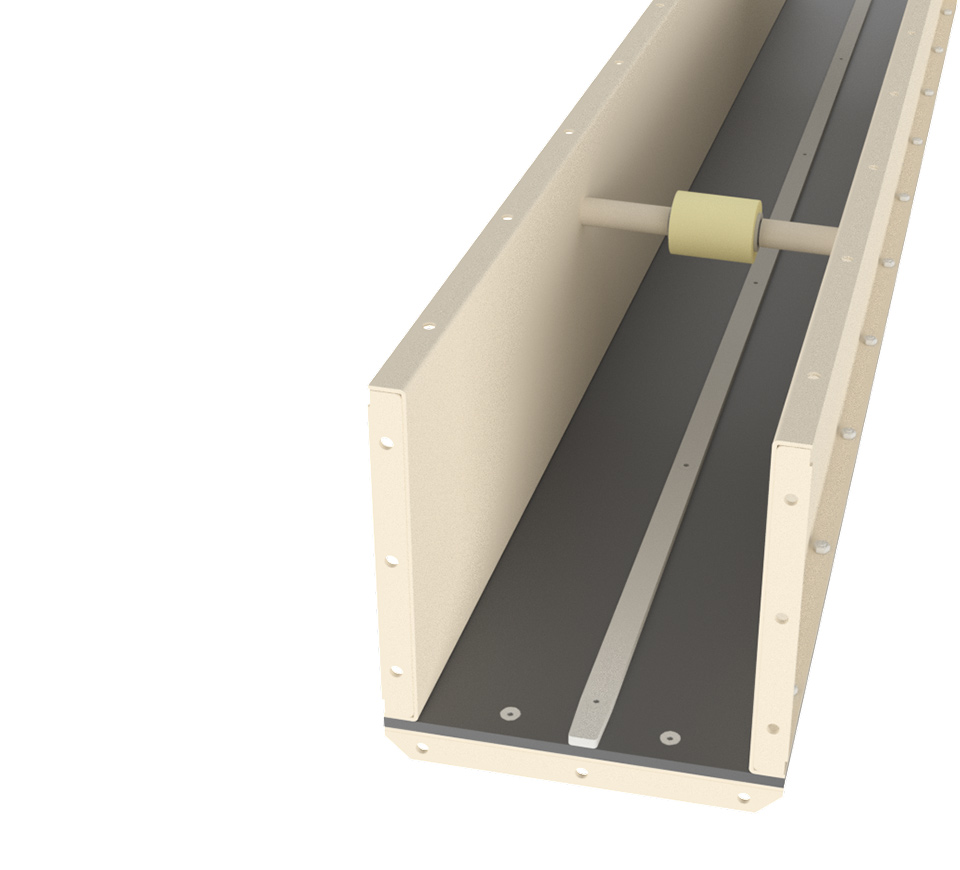

Chain conveyor

A lot of people call chain conveyors “redlers”. We call them chain conveyors, but they are the same type of machine. If a redler is what you require, then our chain conveyors are the ones to choose. If you prefer to call it a redler that’s perfectly fine with us.

Capacity

FM Bulk Handling – Fjordvejs chain conveyors have a standard capacity from 5-900 m3/hour. If you require greater capacity or have other requirements, we are able to manufacture them in custom sizes.

Self-supporting up to 20 m

An FM Bulk Handling – Fjordvejs chain conveyor can support its own weight for spans up to 20 m. This means that no additional support/pillars are required when, for example, the chain conveyor is required to span from one building to another or cross a driveway.

FM Bulk Handling – Fjordvejs chain conveyor standard

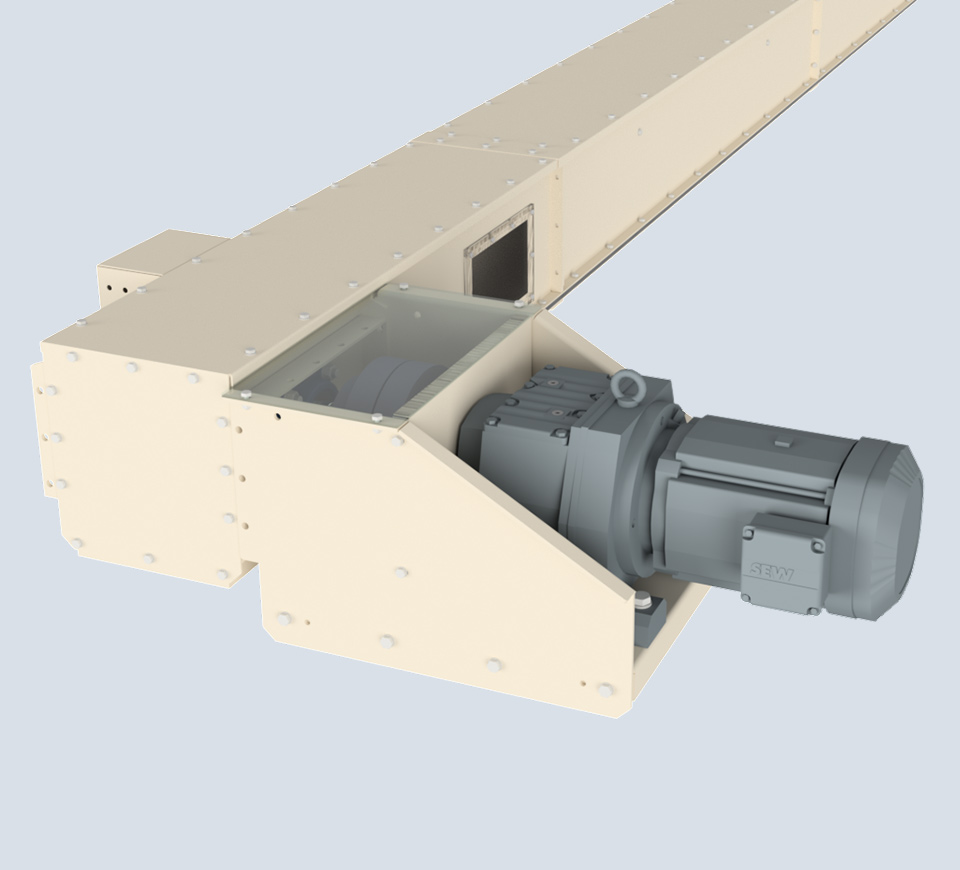

Motor

We use different types of gear motors for our chain conveyors, depending on materials, capacity and running time, or if you have specific requirements:

- Helical gear motor

- Parallel shaft helical gear motor

- Helical bevel gear motor

Our motors are fitted to heavy-duty motor brackets.

Chain conveyor customisation options

FM Bulk Handling – Fjordvejs chain conveyors can be supplied with the following equipment: